Europe aims to manage chemicals more responsibly, to protect the health of its citizens and the environment.

Chromium VI compounds (CrO3) are widely used for their numerous properties, in fact it reinforces adhesion and confers anti-corrosion properties. But Chromium VI is also carcinogenic, mutagenic and repro-toxic (CMR) during inhalation exposure at very low doses.

In this context, CrVI-based compounds are subject to strong regulatory constraints in Europe (REACH regulation). Indeed CrVI is included in the list of substances subject to authorization (Annex XIV) which means that this substance can no longer be marketed (alone or in a product) without a specific authorization delivered by the competent authorities (uncertain, long and expensive process).

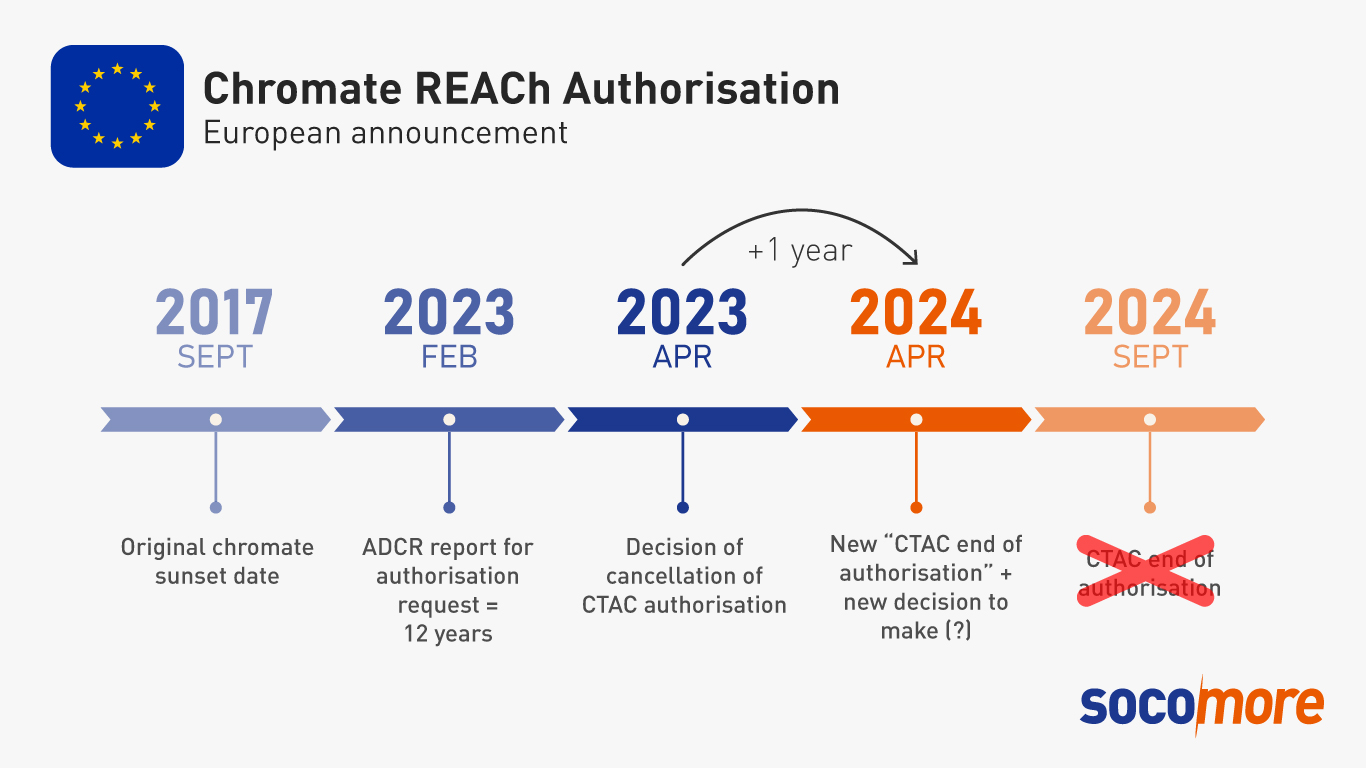

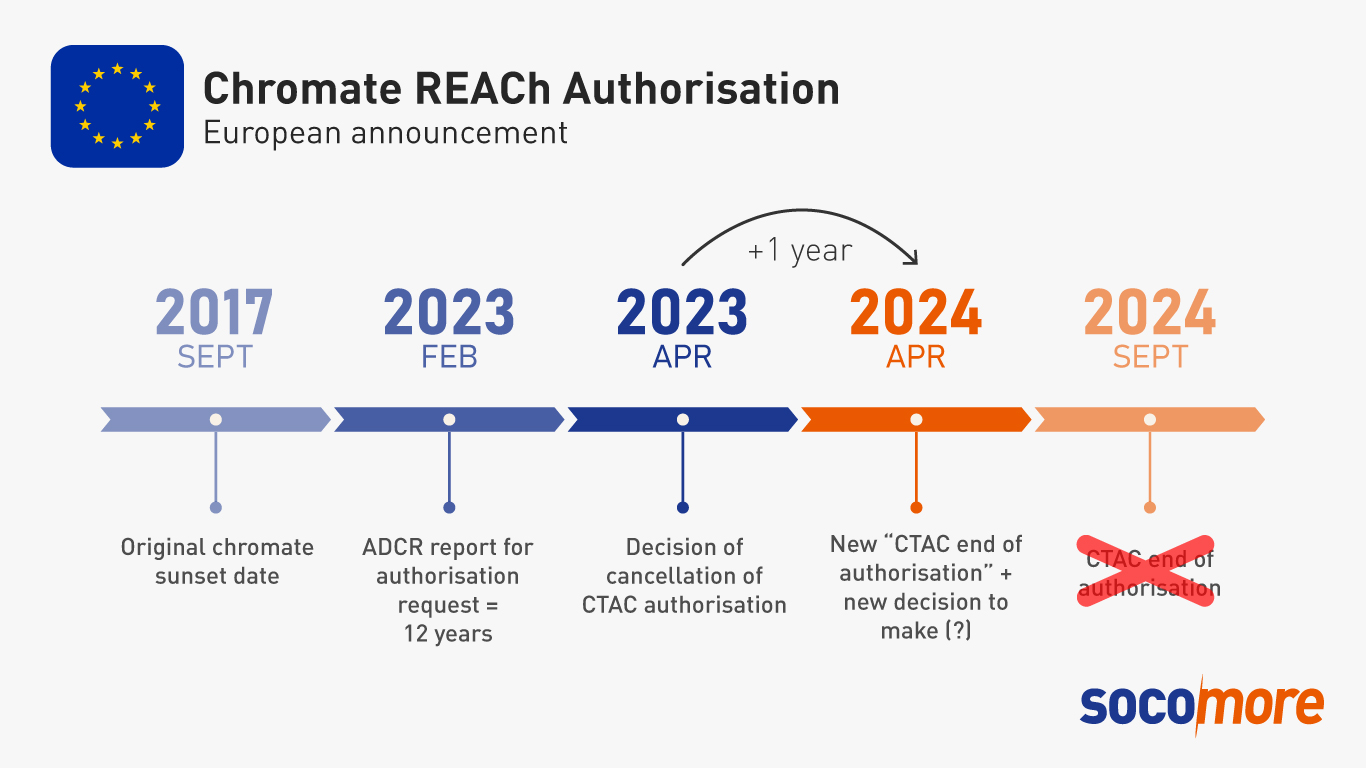

Certain authorizations have been granted for specific uses and for certain companies or groups of companies, as is the case for the CTAC Sub 2 consortium with an authorization running until September 2024.

However, on April 21, 2023, the European Court of Justice annulled the CTAC authorization decision, obliging Echa to take a new decision on this authorization before April 20, 2024. During this period, CrVI can continue to be used under the same conditions, and the decision handed down in April 2024 will determine the future of this authorization.

This decision is a powerful symbol of Europe's determination to eliminate CrVi from the European chemical landscape.

SOCOMORE is actively developing alternative solutions. We have focused on creating treatments with trivalent chromium (Cr III) for aluminum alloys. Our process, named SOCOSURF TCS/SOCOSURF PACS, is a strong alternative to chrome VI. Many major manufacturers already use it.

Main qualifications for SOCOSURF TCS/SOCOSURF PACS process in surface treatment

Qualification - Conversion & sealing of anodisation

| Conversion | Sealing after anodisation |

|

|

Evaluation in progress - Conversion & sealing of anodisation

|

Conversion |

Sealing after anodisation |

|

|

A review of chromium-free coatings: findings from a U.S. study

The elimination of hex-chrome is also a topic in North-America. A recent study by the Toxics Use Reduction Institute evaluated hexavalent chromium-free conversion coatings on different aluminum alloys.

The research compared hex-chrome free conversion coating technologies against the industry standard hex-chrome conversion coating.

The conclusion was that “Overall, the Socosurf TCS/PACS was the best performing hexavalent chromium-free conversion coating across all four types of aluminum alloy. It had the best or tied for the best performance for each alloy type.” (Morose et al, 2022)

Mr. Morose is a research Manager for the Toxics Use Reduction Institute and a Research Professor for the Zuckerberg College of Health Sciences at the University of Massachusetts Lowell. “Evaluation of Conversion Coatings Without Hexavalent Chromium for Aerospace and Defense Applications” https://doi.org/10.1590/jatm.v14.1248

Innovation by SOCOMORE: conversion with colorful touch-up solutions for surface treatment

We continue to develop the SOCOSURF TCS / PACS based on user feedback. Although it is primarily used in immersion, it has also been demonstrated to work in spray and brush applications. Currently, we are developing "ready-to-use" touch-up formats and a dyed version for higher visibility. Our SOCOSURF TCS Colored pens (article) offer the added benefit of coloring the conversion layer and we are on the brink of releasing the SOCOSURF PACS in a ready-to-use touch-up format.

As the aerospace industry adjusts to new regulations banning hexavalent chromium, you can always count on SOCOMORE to provide you with effective and environmentally-conscious solutions.