During the surface treatment process, the aluminium parts will be going from bath to bath in order to obtain different properties. One of the first actions will be to clean the part. Cleaning it means removing inks, oils, grease, etc. from the surface.

SOCOMORE is happy to present from its surface treatment range, an alkaline degreaser approved by major OEMs such as AIRBUS and SAFRAN.

What is the cleaner SOCOCLEAN A3432?

SOCOMORE’s cleaner was developed in order to offer a complete range of REACh compliant solutions for aluminium surface treatment. The aqueous degreaser SOCOCLEAN A3432 is borate free. SOCOCLEAN A3432 works perfectly on cleaning operations before deoxidizing or desmutting, especially with SOCOSURF A1858/A1806.

The main application for SOCOCLEAN A3432 will be on aluminium parts however it can also be used on titanium or stainless steel alloys.

The cleaner is specifically intended to replace degreasing baths with sodium borate because this substance is now registered in the SVHC’s list (Substances of Very High Concern). It is the list of extremely high concerns issued by the European Agency on chemical products (ECHA) within the frame of REACH regulations. Sodium borate is also in the “Candidate List” priority substances of Annex XIV of REACH (the “Authorisation List”).

The degreaser can be used :

- by immersion

- by spraying.

To find out more about SOCOCLEAN A3432, check out our article about chromate and fluoride-free aluminium

For more information on SOCOCLEAN A3432, click on the image below to view its product sheet:

New qualifications

The alkaline degreaser SOCOCLEAN A3432 keeps on being attractive for companies. The product was approved by FOKKER LANDING GEAR and SAFRAN according to PR1500 and IN1500. The borate free cleaner is now approved by AIRBUS and listed into process specification:

- AIPI02-01-003 Tartaric Sulphuric Anodizing of aluminium alloys (TSA)

- AIPI09-01-003 Cleaning with aqueous cleaning agents, Called by AIPI02-05-001 (Chemical Conversion Coating, CCC) and AIPI02-01-002 (SAA: Sulphuric Acid Anodizing of aluminium alloys)

- AIPI02-01-006 Phosphoric Sulphuric Anodising (PSA) of Aluminium Alloys prior to Structural Bonding

SOCOMORE is glad to walk in the same direction with AIRBUS offering on the market products for Chrome VI free aircrafts, according to ACF project (Airbus Chrome Free Projects).

What makes the SOCOCLEAN A3432 unique?

Thanks to the new AIRBUS qualifications, SOCOCLEAN A3432 becomes an attractive aqueous cleaner for aerospace subcontractors.

Formulation

The alkaline degreaser is borate and silicate free and REACh compliant. Until now most approved cleaners in AIRBUS process specification contained borate salts. As a reminder borate salts are classified as CMR (Cancérogène, mutagène et reprotoxique). It means hazardous risk according to H 360: may damage fertility or the unborn child.

Thanks to its formulation SOCOCLEAN A3432 avoid VOC emissions, limiting the risk for operators to inhale hazardous substances. To read more about solutions to reduce VOC, read this article.

Degreasing and de-inking capacity

The de-inking capacity of the product replaces manual cleaning of parts with solvent cleaners. It reduces the process of non conformance due to lack of ink removal, like visual issues or absence of treatment locally.

Additives

The degreaser comes with a dedicated reinforcing additives range.

- SOCOCLEAN DB boosts the degreasing properties

- SOCOCLEAN IR has very strong de-inking capacities, it will increase the bath lifes’ expectancy from 30 to 80 %

- SOCOCLEAN AF is available as an anti-foaming additive.

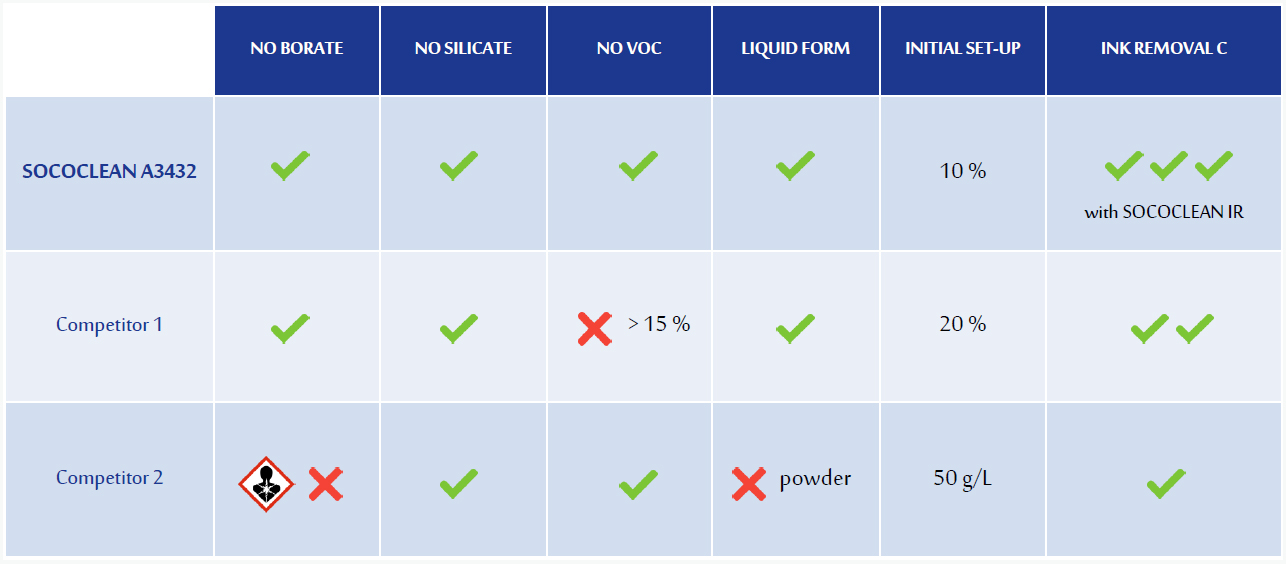

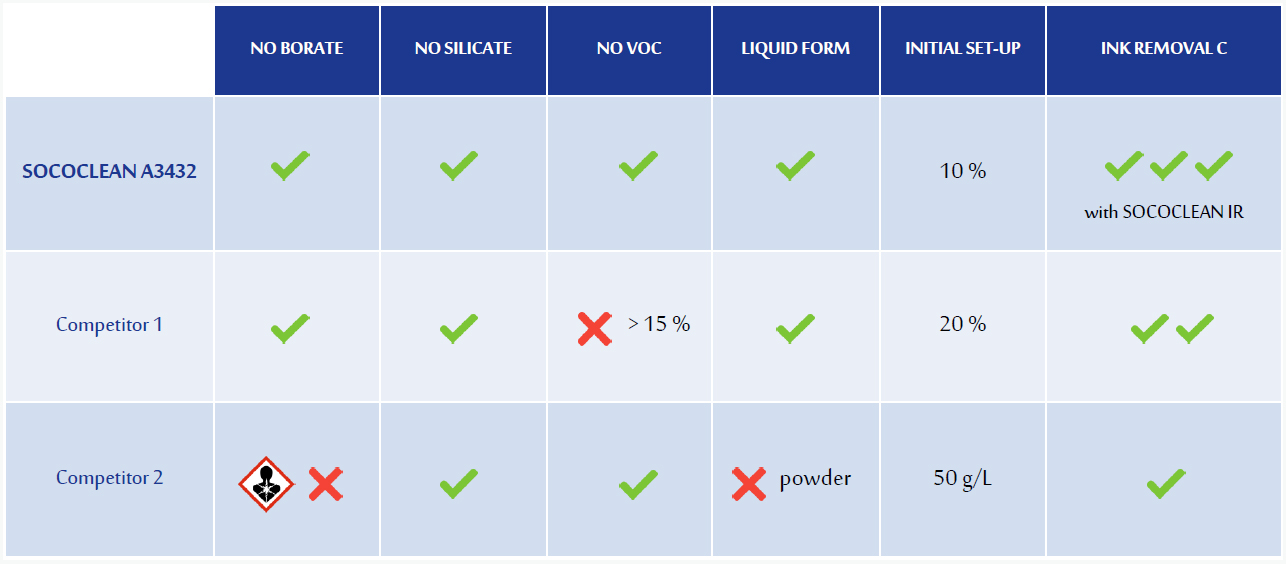

Cleaners comparison

Among AIRBUS qualified cleaners, SOCOCLEAN A3432 is at the top of the most efficient and non-toxic degreaser for surface treatment. Below a comparison of 3 chosen products.