SOCOMORE has launched its own dry wipe solution SOCOWIPES 21800 qualified to the AMS 3819D aeronautical standard. The specialist of surface preparation and presaturated wipes complete now his offer with a proprietary AMS3819 dry wipes solution use for wipe on and wipe off operations for critical aerospace applications.

SOCOWIPES 21800 : the aerospace grade wipes solution from SOCOMORE

SOCOWIPES 21800 is the new dry wipe developed by SOCOMORE for surface cleaning, surface preparation and finishing application in the aerospace industry.

Specifically designed with the right amount of wood pulp & polyester fibres, it offers the best combined functions such as:

- excellent durability

- high absorption capacity

- good release capacity

- In differents formats & packagings

Features and benefits of SOCOWIPES 21800

The SOCOWIPES 21800 offers the following advantages, making it a good choice for critical applications in the aerospace industry:

- Exceptionally clean

- Contains no binders

- Very absorbent

- Creped design to collect & retain contamination

- Low linting

- Durable, maintains strength when wet

- Solvent resistant

- Silicone free

SOCOWIPES 218000 applications

SOCOWIPES 21800 are used in surface preparation before coating, sealant, or adhesive application. Originally designed for aerospace grade, they can also be used in all critical wiping operations such as these following activities:

- Aerospace vehicle production

- Composites manufacturing

- Laboratories and production areas

- Heavy equipment maintenance

Thanks to their good durability and highly absorbent, they are also very efficient for all general cleaning & degreasing applications including removing excess sealant.

Wipes can be used in several application ways:

- with a spray or a wash bottle on surface as a wipe on

- by saturating the wipes manually

- or for wipe off

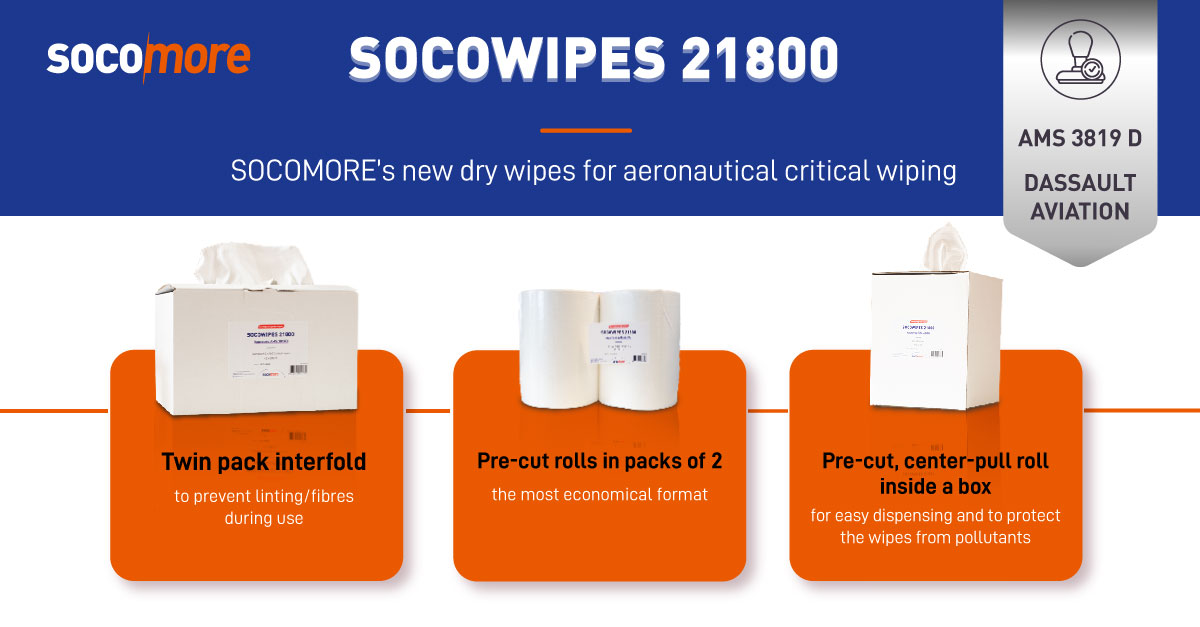

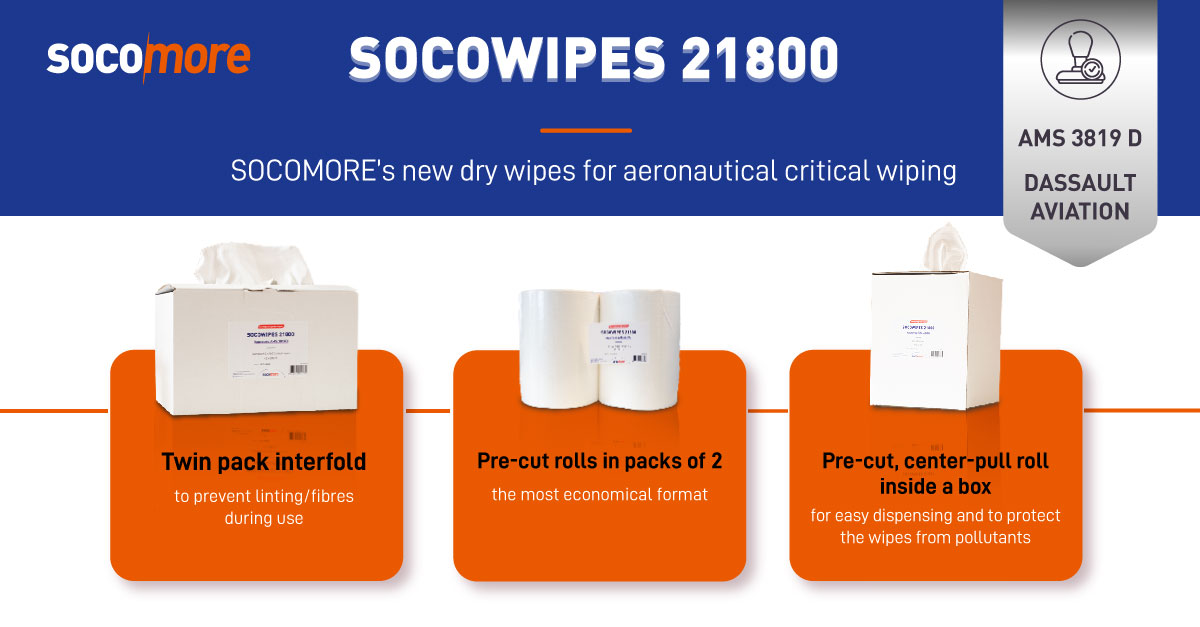

3 formats of SOCOWIPES 21800 for your needs

The dry wipes SOCOWIPES 21800 are available in 3 packaging versions to meet your critical cleaning challenges:

- Twin pack interfold to prevent linting/fibres during use. The interfold allows you to easily pull the wipes.

- Pre-cut, center-pull roll inside a box: this eases dispensing and protects wipes during the use of pollutants.

- Pre-cut rolls wrapped by 2: this is the best cost format.

|

Description |

Size (cm) |

Number of roll |

Number of wipes |

Packaging |

|

Pre-cut roll wipes wrapped by 2 |

38x30 |

2 |

800 (2x400) |

No box |

|

Pre-cut roll wipes inside a dispensing box |

38x30 |

1 |

400 |

Distributing box |

|

Twin pack folded wipes |

42x30 |

N/A |

320 (2x160) |

Distributing box |

SOCOWIPES 218000 approvals and grade

- AMS 3819 D compliant: it can be used by MRO on AIRBUS or BOEING aircraft

- DASSAULT AVIATION DGQT 1.5.0.0001 approval for critical application

What is the AMS3819D standard?

AMS3918D standard purposes

The AMS3819D is the recently updated standard of the historical AMS3819. The latest version of the AMS 3819 standard was released in July 2020. It details a new way of managing aircraft maintenance processes supported by new technologies. Published by SAE International, AMS 3819D is the aerospace industry quality standard for wipes used for cleaning aircraft primary and secondary structural surfaces, especially dry wipe.

Cloths, Cleaning For Aircraft Primary and Secondary Structural Surfaces AMS3819D

This specification covers woven, nonwoven, and knit absorbent materials supplied either as dry cloths or presaturated cloths for solvent cleaning process applications. This standard is the reference for efficient and compliant dry wiping for Aerospace applications.

What is dry wiping

Dry wiping is mainly used to prepare the aircraft surface before application (coating, sealant, adhesives). It can also be used to remove excess of these previous materials.

The dry wiping process is one of the most challenging tasks in cleaning parts & structures of an aircraft during manufacturing & maintenance operations. Achieving a thorough cleaning at high speed while reducing contamination and waste can be difficult with conventional wipes.

Aeronautical critical wiping requires the best technologies on the market, a wipe that generates little if no waste on the surface of the aircraft. That is the role of AMS 3819 D

How to meet the AMS3918D standard?

To meet the standard, cloths must meet rigorous specifications and manufacturing requirements. The AMS 3819D specification eliminates recycled and reclaimed materials, thus ensuring a clean-wiped surface to which paint, sealant or adhesive will adhere. The standard not only requires that all materials need to be tested, approved and listed on AMS QPL but also a control of every batch of production through the initial test protocol.

The AMS 3819 revision D ensures users a perfect compatibility with the treated surfaces. Also it minimises the risks of cross-contamination (particulate and chemical). The wipes must also be durable and highly absorbent to ensure fast drying in your process and without lint.

The conclusion of the Product Manager, Benoît Côte

“Available in three types of packaging, SOCOWIPES 21800 is the right choice to meet your expectation in degreasing operations or for more demanding tasks such as pre-paint or pre-bonding surface cleaning”