SOCOMORE fights against erosion problems in the aerospace industry! Among the wide range of products available in the group, you will find the erosion protection coatings. Spotlight on this range specially designed to protect your external surfaces, in particular the leading edge, more exposed to erosion.

SOCOMORE erosion protection coatings are high performance protective coatings. Once applied, they protect metal and composite parts of your equipment and prevent the following problems:

- Abrasion

- Sand erosion

- Rain erosion

- Particles damage

Erosion protection coatings: a SOCOMORE expertise

Protect your parts against erosion

SOCOMORE is the leader in erosion protection coatings for the aerospace industry. Indeed, our high performance coatings are currently used on multiple aircrafts:

- Commercial aircraft

- Helicopter

- Military aircrafts

- Antennas

A range of approved coatings

Our erosion protection products are approved by leading users, in particular for our Mader Aero range. Aeroglaze and Chemglaze coatings are qualified by the U.S. Air Force and the U.S. Department of the Navy. They are also approved by major aircraft and engine manufacturers, including Boeing, Lockheed Martin and Pratt & Whitney.

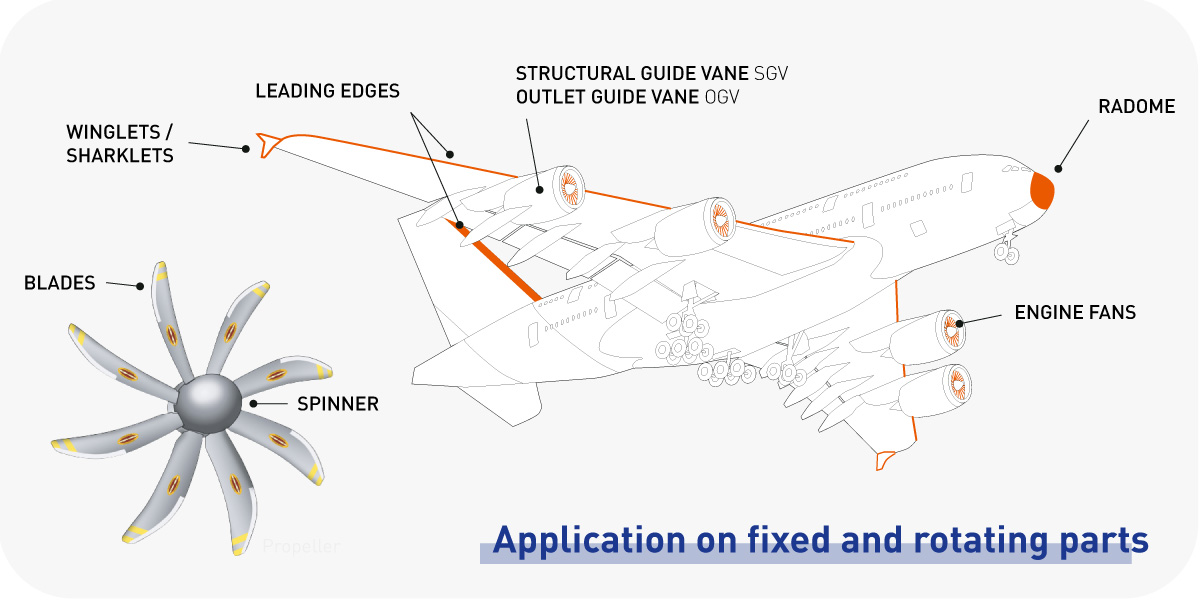

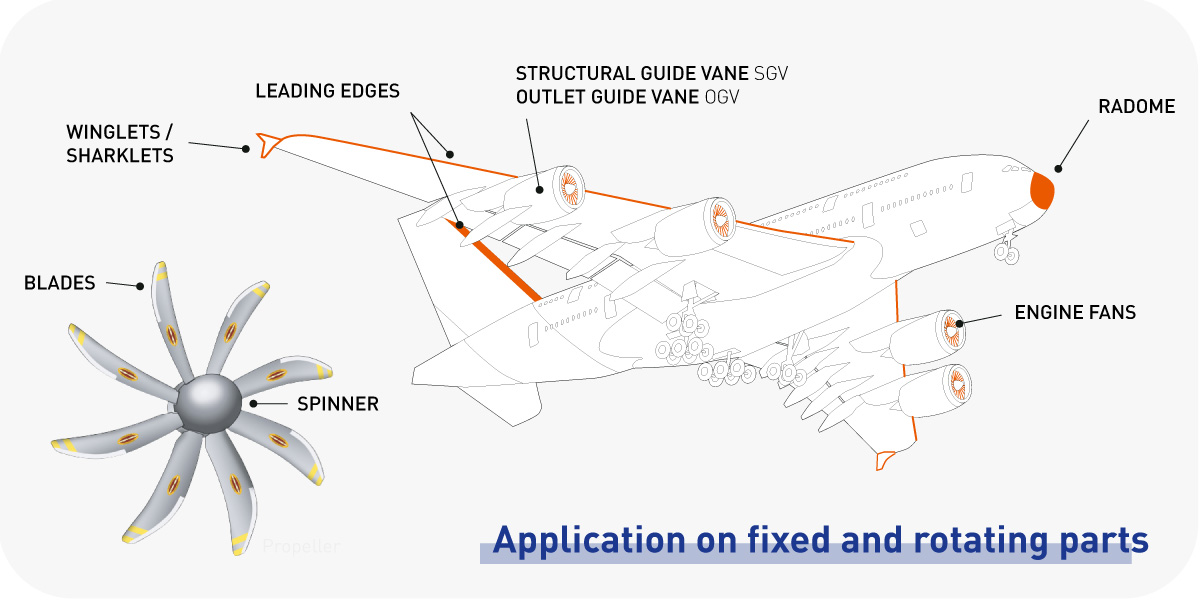

Erosion protection: multiple applications

Fixed parts protection

The protection from erosion of your fixed parts on aircraft or helicopters will increase their service life. To do this, use erosion protection coatings as a final coating to protect your parts. This applies to :

- Radomes

- Leading edges

- Wings

- Winglets

- Sharklets

- Or any other composite parts

Protect rotating parts

The rotating parts of the equipment are subject to a lot of friction (air, sand, rain, particles, etc.). Because of their rotation, they are even more at risk than fixed parts and should be protected as a priority. Preventing their erosion is essential to increase their life cycle. This applies to :

- Spinner

- Engines fans

- Propellers

- Outlet guide vanes (OGV)

- Structural guide vanes (SGV)

- Helicopter blades

- Ground antennas

Why choose SOCOMORE coatings?

A full range to fight against erosion

Increase the life of your aerospace equipment in service with a full range of erosion protection primers and topcoats. Protect your metal and composite parts from sand erosion, rain erosion, and abrasion.

SOCOMORE coatings are solvent or water based to meet everyone's needs. The thickness of the finish coating can be adapted to your needs. This way, you can save weight while maintaining its performance.

Finally, our range of erosion protection coatings offers excellent chemical resistance, especially to phosphate ester-based hydraulic fluids, which ensures its good resistance, even on exposed areas.

Our experience at your service

SOCOMORE experts can help you analyze your needs and guide you towards the best solution. Depending on your issues and challenges, we are here to help you make the right choice.

For example, depending on the type of erosion you are dealing with, you will not have to choose the same coating. A coating that is resistant to sand erosion will not automatically be resistant to rain erosion. Our many years of experience and expertise will help you choose the best erosion protection coating.

Our erosion protection coatings meet all your needs

Do you want to reduce your VOCs and your operating times while increasing your regulatory compliance? SOCOMORE coatings will help you meet all your challenges while providing additional features for each coating.

Coatings for each function

Our range of coatings is highly technological. It goes far beyond the simple protection coating to serve other functions, such as:

- Conductivity: Our AEROGLAZE Z307 product is an electrical conductive polyurethane coating that helps dissipate static charges.

- Appearance: Our coatings are available in different colors and/or can be overcoated with a colored topcoat.

Compliant coatings

From a legal and human health aspect, SOCOMORE tries to combine efficiency and compliance. Our new product ranges are developed with a focus on regulations, environmental awareness and health. And offer solutions:

- without CMR components

- with very low VOC emissions

- REACH compliant

- TSCA compliant

Would you like to know more about our erosion control coatings?

Download our brochure to discover the whole range.