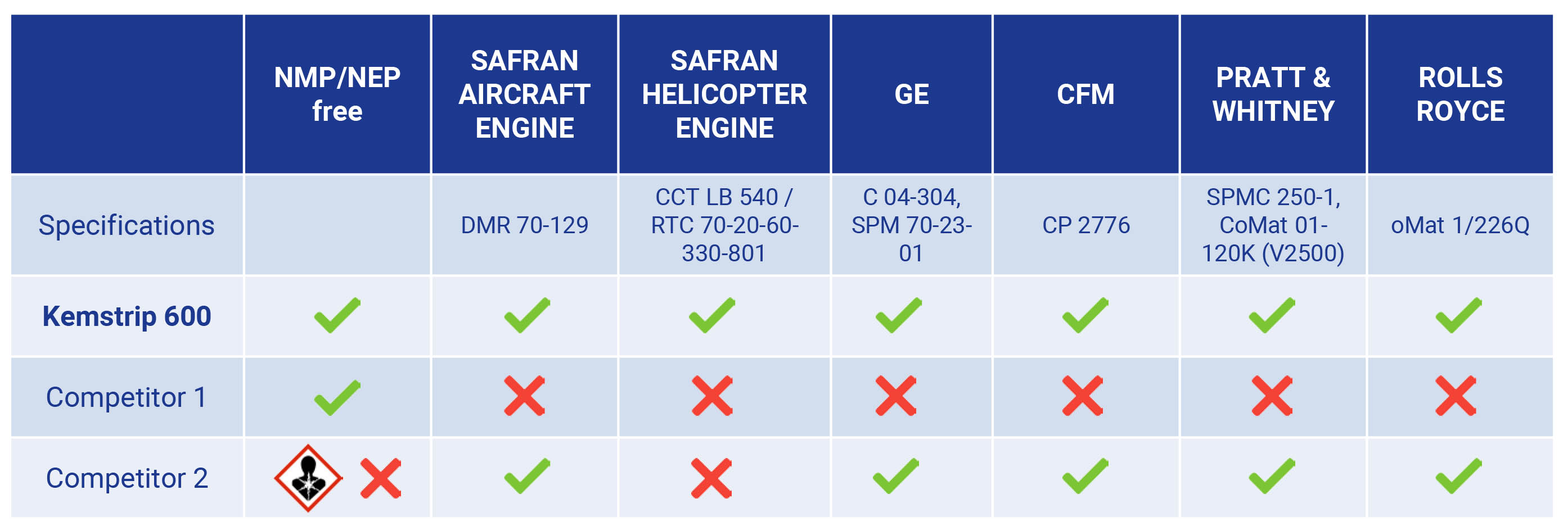

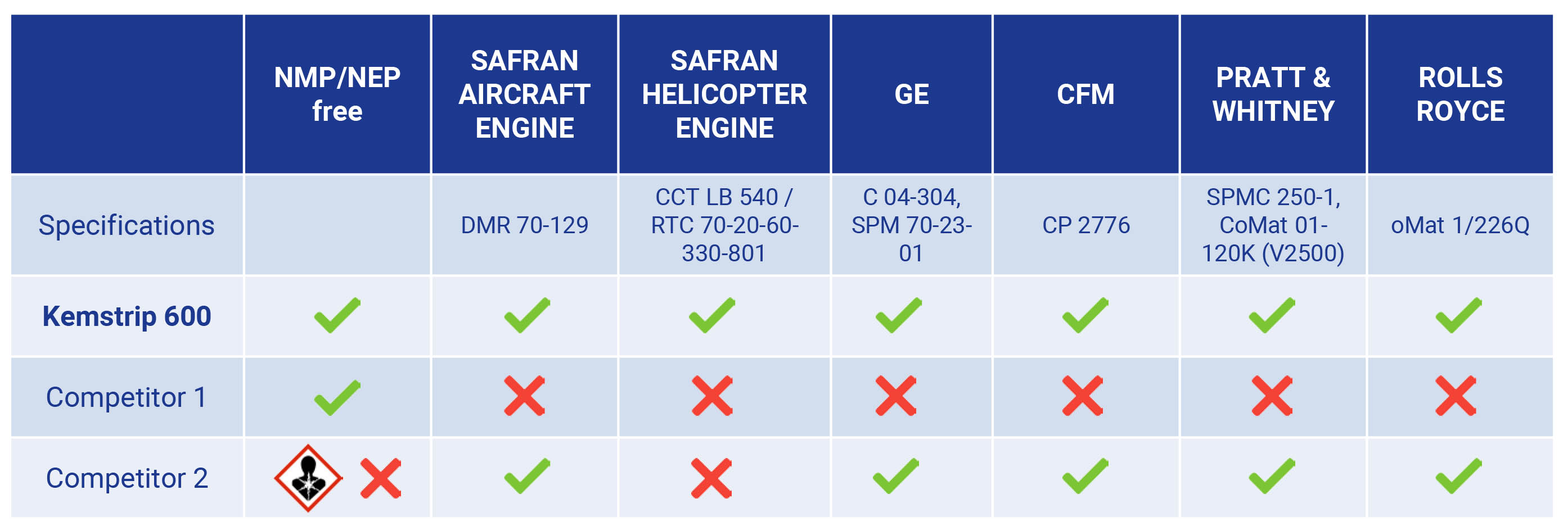

With the latest qualification by Rolls-Royce of the KEMSTRIP 600 paint stripper, SOCOMORE is the first and only supplier to offer a product qualified by all manufacturers of engines for civil & military aircraft, and in compliance with REACh regulations.

Since May 9, 2020, the REACh regulation prohibits NMP (N-methyl-2-pyrrolidone) at a concentration greater than 0.3% (ECHA). Also, aircraft manufacturers are forced to replace their paint stripping products particularly used on painted engine parts.

To help them, SOCOMORE has developed a product without NMP, NEP and Chrome (VI), which allows it to be environmentally friendly. This new “REACH compliant” product is very effective on thick or multiple coats of paints, on carbon / scale of engine components subjected to very high temperatures, but also on landing gears and brakes.

After months of development and testing with customers, the KEMSTRIP 600 is now qualified by all major aircraft manufacturers.

The fact of being listed in the manufacturers' manuals for maintenance allows all engine maintenance centers to use the KEMSTRIP 600, without differentiation according to the type of engine. It has demonstrated its stripping efficiency, which has facilitated its implementation with several customers, for stripping landing gear, wheels and brakes (conform to BOEING D6-17487 / BSS 7432 / SAFRAN PCS 2700 appendix A). KEMSTRIP 600 is an alternative to depainting by plastic media, with savings for operators in terms of cost, depainting time, ease of implementation and HSE.

This is also in response to changes in regulations prohibiting the use of NEP/ NMP, SOCOSTRIP A4512, which can be used at room temperature, also allows part stripping in other industry sectors.