R&D

Customer oriented innovation is at the heart of the SOCOMORE Group strategy.

“Our objective is to meet our customer's current and future needs.”

– Philippe TINGAUT, Chief Technology Officer of SOCOMORE

4 Working Axes

1. Continuous Product Improvement

Products need to evolve in order to meet the ever-changing industry and regulatory requirements. At SOCOMORE, we are continuously working to improve our product portfolio. We constantly review formulas, legislation, packaging, and application requirements to ensure our products continue to benefit our customers. Our portfolio includes colored variations of sol-gels for clear visibility on where the product is applied, touch-up solutions that reduce waste and costs on small repairs, and ready-to-use products that help to speed up the application process, etc.

2. New Product Development

SOCOMORE develops tailor-made solutions in response to customer issues. Whatever the requirement; reduce the weight of an aircraft, limit VOC emissions, automated robotic cleaners, REACh compliant products, low or ultra-low density sealant, sealant with improved chemical resistance or a specific kinetic profile, etc., SOCOMORE adapts to the customers’ requirements, and can work with customers to co-create specific solutions.

3. Product Durability & Safety

Quality, long-lasting product is of key importance to customers. At SOCOMORE, we ensure we have a dual supply source and test the quality of raw materials in our production factories. With manufacturing and trading subsidiaries in Canada, the USA, Ireland, and France, and key partners in North America, South America, Asia, and mainland Europe, we cater to customers worldwide. Our laboratory teams work on product industrialization so products are produced to the same standard in all our factories and partner facilities.

Our teams monitor Health, Safety & Environment regulations and take any regulatory changes into account. Our research protocols target the reduction of VOC (Volatile Organic Compound) emissions and the substitution of hexavalent chromium and other CMR (Carcinogenic, Mutagenic, Reprotoxic) substances via a new generation of REACh compliant products.

Our Quality Management System means our customers can be assured that our products are produced in a standardized process, are of consistent quality, and are fully traceable.

4. Innovation

Innovation is essential in aerospace. Our customers require lightweight products to reduce the weight of the aircraft for better fuel efficiency, reduced CO2 emissions, and costs. They also require customized solutions, standardized operations, and much more. To meet their requirements we don’t just work with our own expert laboratory team. We are also part of project consortiums and welcome those working on doctoral theses. We follow a technical roadmap that is aligned with the industry’s key trends and innovation drivers. The product development axes we work on enable us to continue to offer innovative solutions to customers in line with their economic, environmental, and regulatory needs.

Teams & Technology

Our Scientists & Engineers

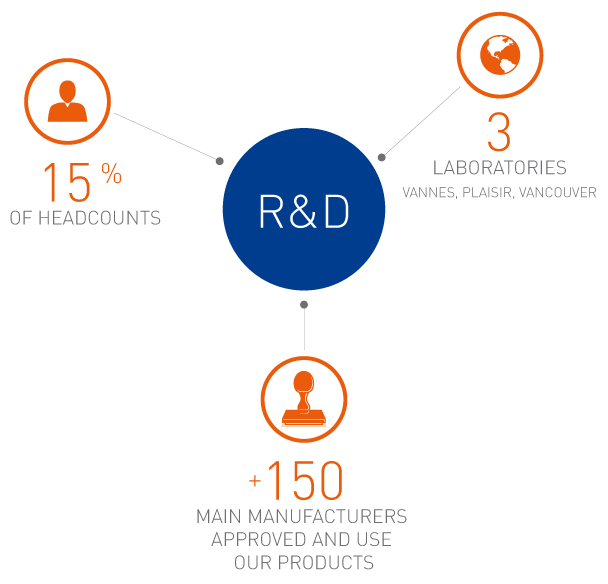

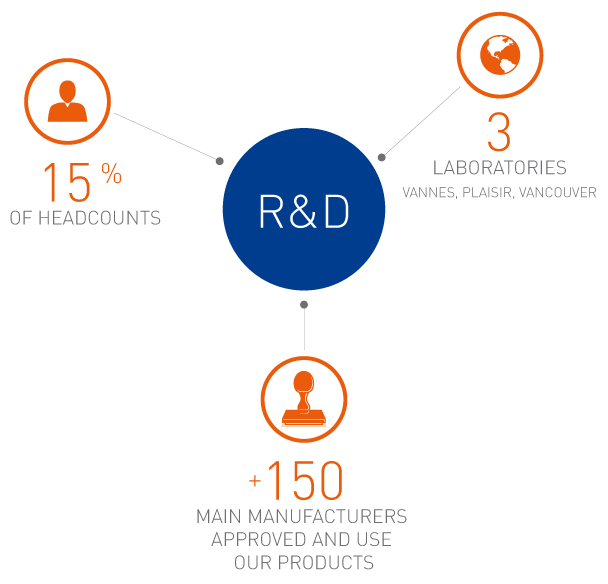

Our scientific expertise in material and mineral physics, organic chemistry, electrochemistry, and textiles, in combination with our laboratories, is at the center of our product development strategy. Our engineers, doctors, and technicians work in partnership with our clients and our experienced technical support teams. They have an in-depth knowledge of the technology used by our clients, their work methods, the complexity of their processes, and their constraints. Based in North America, Asia, and Europe, our technical teams contribute to the technical specifications of our clients. They support our sales teams and clients, training them in the use of our products on site.

Approvals

We offer a variety of aerospace-approved products that meet all the specifications required by the major OEMs and MROs. More than 60 of the main aircraft manufacturers have approved and use our products. Our R&D and technical support team work together to qualify more products every year for existing programs. We also aim to be present and active in targeted new commercial, military, and engine aircraft programs such as the Airbus A320neo, Airbus A350, COMAC C919, Bombardier C Series, Boeing 787, Embraer E-Jet E2 family, Irkut MC-21, and the Mitsubishi Regional Jet (MRJ), to name a few.

Lab Testing

As we are constantly testing new products and applications, our laboratories are equipped with their own test equipment for analysis, application, and material characterization testing. For high specification testing, we utilize reputable external laboratories that use cutting-edge technology.

Technology

Our products are the fruit of our R&D and global technology partnerships. We actively participate in research programs lead by universities and technical centers in Europe and North America. We also work with global manufacturers on the development and qualification of products and co-develop products with our partners and customers. We participate in technical conferences every year to actively increase our knowledge and follow the latest developments and advances in chemistry and the aerospace industry.

A new laboratory in Vannes (France)

Our global R&D center is based at our headquarters in France. Our expert teams have been solving manufacturing and regulatory issues here since 1972.

For upstream studies, our laboratories are equipped with the resources necessary for analyses and material characterization testing. A new purpose-built laboratory is under construction at SOCOMORE HQ in Vannes, with the aim of extending and modernizing the current laboratory to better support the future needs of our customers.

SOCOMORE also has R&D experts based around the globe so they can be close to our customers and support them in their projects.